-

products

-

Industries

-

Services

In the world of material handling, certain industries or processes demand conveyors that go beyond traditional designs. Our “Special Conveyors” category is dedicated to catering to these requirements, offering a collection of conveyors that push the boundaries of conventional design and functionality. Here, you will discover a variety of unconventional and custom conveyor solutions that address specific material handling challenges across diverse industries.

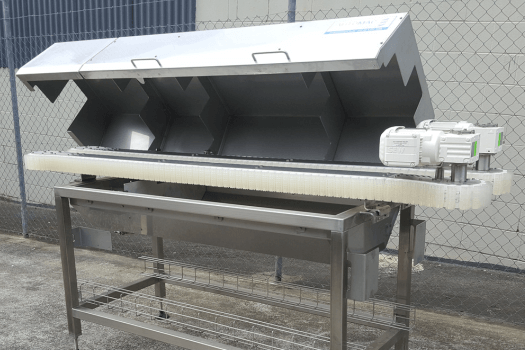

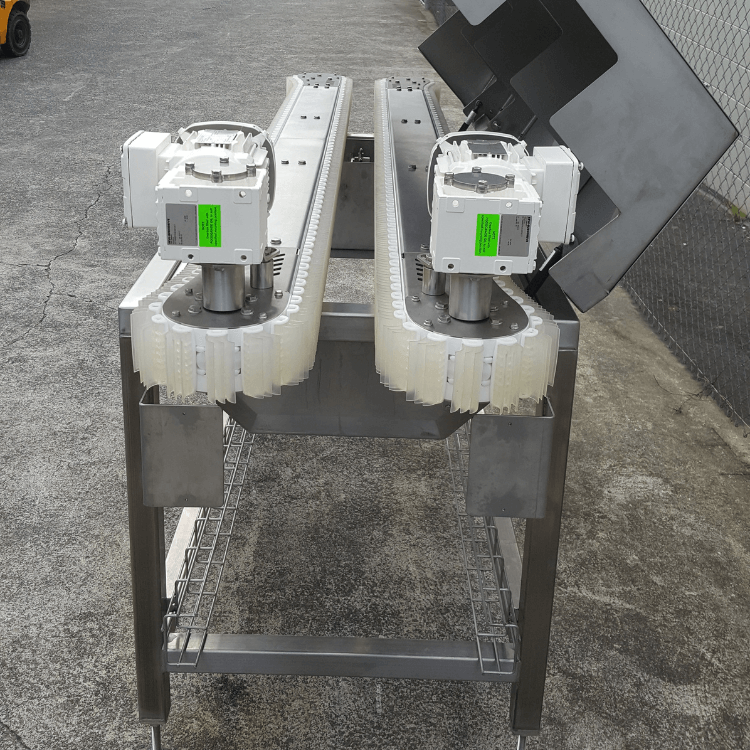

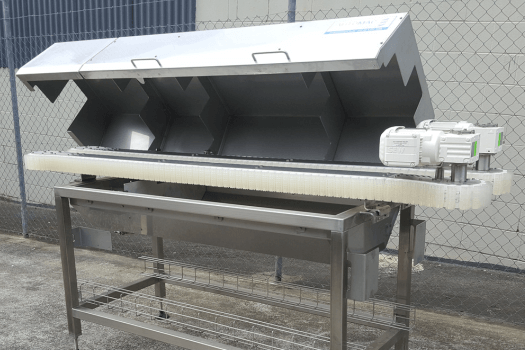

“Special conveyors” are conveyors typically designed for specific purpose. This includes bottomless conveyors (side drive), spreader conveyors, odd shapes, integration with troughs and other product handling equipment.

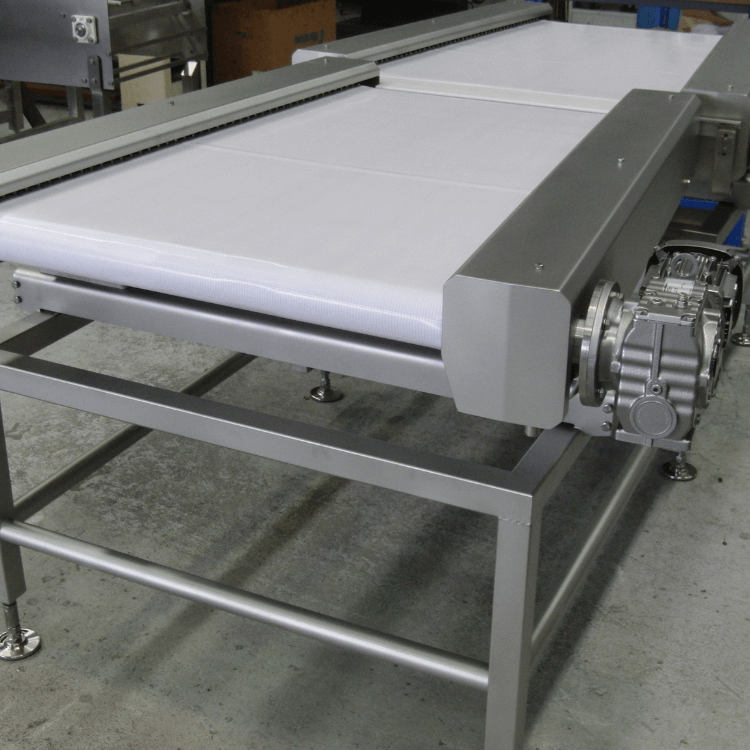

Side Drive Conveyors: Side drive conveyors are a type of conveyor system where the drive mechanism is located on the side of the conveyor, parallel to the conveying surface. This design allows for compact and efficient power transmission, making side drive conveyors suitable for applications with limited space or where a centralized drive is not feasible.

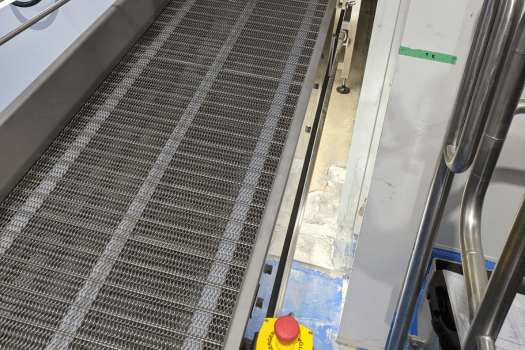

Wire Mesh Belt Conveyors: Wire mesh belt conveyors feature a continuous metal belt made of interlinked wire mesh. This style of conveyor is well-suited for applications that require airflow or where the product being conveyed needs to be cooled, drained, or undergo processes such as washing or drying. Wire mesh belt conveyors are commonly used in the food industry.

Spreader Conveyors: In the FMCG industry, snack bars are often made from slicing a large slab of product into skinnier “ropes”. Once slit, the product needs to be seperated so that bars can be processed seperately. This is where a spreader conveyor is used as it seperates the product. This most commonly achieved using an elastic belt which stretches causing the gaps between each rope to increase.

Roller Draw bridge: When you need access through a conveyor line, perhaps for a forkhoist or pallet trolley, our roller conveyor draw bridges are a great solution. These conveyors can easily be lifted by hand and stay in place using gas struts.

Top Hold Down Conveyor: When transporting items down an incline, there is potential for them to slip on the belt and slide uncontrollably down the conveyor. To solve this problem, we utilised grip top modular belt to act as a weight to hold product onto the conveyor. With the items held in place, they are conveyed downhill with ease.