-

products

-

Industries

-

Services

Case Study

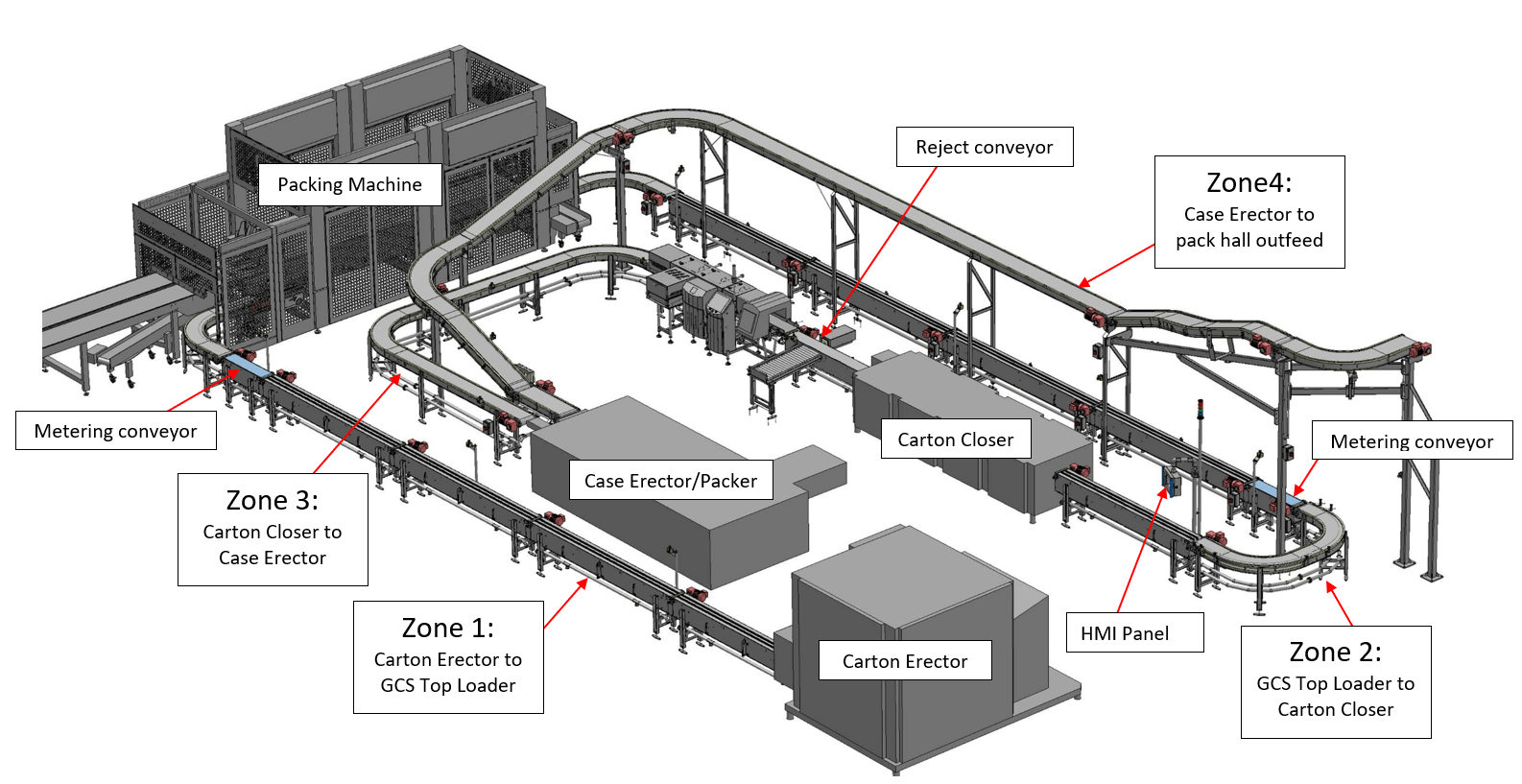

Integrating our conveyors with the carton erecting and packing equipment, we facilitated the packaging process. The product was packed into cartons, which were then placed into shipping cases for distribution. However, accumulating open cartons presented a unique challenge due to their delicate nature. Traditional accumulation methods using simple stop plates were unsuitable as they risked crushing or dislodging them. To address this, we devised an solution utilizing multiple conveyors equipped with roller top modular belts that could automatically start and stop as needed. This intelligent system minimized accumulation back pressure, safeguarding the product from damage. Additionally, friction top modular belts were employed to act as stops while also aiding in re-gapping the cartons for precise transfer in to the next process. Thanks to this advanced setup, the production line could handle up to 45 seconds of stoppage in specific areas without affecting the overall operation.

To ensure the efficacy of our designs, we used 3D simulations to comprehensively analyze the entire system and identify potential challenges. With the simulated environment, we fine-tuned the control logic required to effectively manage these conveyors, streamlining the commissioning process and ensuring a seamless transition to full-scale operation.

From the initial design and manufacturing, code development, installation and commissioning, our team provided end-to-end support throughout the entire project. With our commitment to success, we ensured the project achieved its objectives and delivered exceptional results.

Tip Top embarked on a significant production upgrade, installing a new ice cream manufacturing line. Our role was to optimise the conveyor system and layout, ensuring ample accumulation capacity to prevent production line stoppages in the event of equipment jams. Considering the time-sensitive nature of frozen product and the undesirability of interruptions, the accumulated product then needed to recover from a stoppage by temporarily increasing production rates.